OrlenOil

Industrial Catalogue /

14

OrlenOil

Industrial Catalogue

/15

GEAROILS

GENERALDESCRIPTION:

TRANSOL® SP industrial gear oils aremade from selectively refinedmineral oils; they contain lead free additives im-

proving lubricating properties (sulphur-phosphorus type) and a set of anticorrosive, antifoaming, anti-emulsifying

additives aswell as additives increasing resistance tooxidation. Theoils ensureprotection fromexcessiveoperational

wear to gear elements, i.e. toothed wheels, as well as rolling and sliding bearings in normal operation and in the

case of impact loads, protection of gear elements made from steel and non-ferrous elements from corrosion and

the chemical impact of active ingredients of oil and its oxidationproducts; due tohigh thermo-oxidant stability they

ensureprolongedoperationat increased temperatureswithnocompromise toproperties.

APPLICATIONS:

TRANSOL® SPoils are intended to lubricate heavy-dutymechanical gears of industrial equipment, often transferring

impact loads e.g. rolling equipment inmetallurgical machines, constructionmachinery, cement mill machines, lifts

and transport equipment in shipbuilding industry, machine tools, steam and gas turbine gears, paper industryma-

chines, andother equipment.

GENERALDESCRIPTION:

TRANSOL®CLP industrial gear oils aremade from selectively refinedmineral oils. They ensureprotection fromexces-

siveoperationalwear togear elements, i.e. toothedwheels aswell as rollingand slidingbearings innormal operation

and in the case of impact loads, protection of gear elementsmade from steel and non-ferrous elements from cor-

rosion and the chemical impact of active ingredients of oil and its oxidation products; due to high thermo-oxidant

stability theyensureprolongedoperationat increased temperatureswithnocompromise toproperties.

APPLICATIONS:

TRANSOL® CLP oils are intended to lubricate heavy-duty mechanical gears of industrial devices often transferring

impact loads e.g. rolling devices inmetallurgical machines, constructionmachines, cement mill machines, lifts and

transportdevices in shipbuilding industry,machine tools, steamandgas turbinegears, paper industrymachines, and

other equipment operating at temperatures up to 120°C, requiring oils with increased resistance of the lubricating

film (they contain Extreme Pressure (EP) additives), good thermo-oxidant stability at higher temperatures andgood

demulsifyingand rust protection (to ironandnon-ferrousmetals).

VISCOSITYGRADE:

ISOVG: 68, 100, 150, 220, 320, 460, 680, 1000

QUALITYCLASS:

ISO12925-1CKC/CKD

APPROVALS:

TRANSOL®SP68–CHOFUM-OBRABIARKI

TRANSOL®SP220–GLIMAG, FMGPIOMASA

TRANSOL®SP320–GLIMAG, FMGPIOMASA,

REMAG, RYFAMA

MEETSREQUIREMENTS:

PN-90/C-96056,DIN51517cz.3,USSteel224,

AGMA/ANSI9005-E02; ISO12925-1CKC/CKD

VISCOSITYGRADE:

ISOVG: 68, 100, 150, 220, 320, 460, 680, 1000

QUALITYCLASS:

ISO12925-1CKC/CKD, ISO–L–CKD

APPROVALS:

TRANSOLCLP100,150,220,320,460 -

FLSMIDTMAAG Gear -GEARS60752

TRANSOLCLP150,220,320 -

Schuller -MüllerWeingarten -DT55055

TRANSOLCLP220 -BUMECHSA,GLIMAG

TRANSOLCLP320 -BUMECHSA,GLIMAG

MEETSREQUIREMENTS:

DIN51517cz. 3,USSteel 224,AGMA/ANSI

9005-E02, ISO12925-1CKC/CKD

USSteel 224,AGMA/ANSI 9005-E02

ISO12925-1CKC/CKD

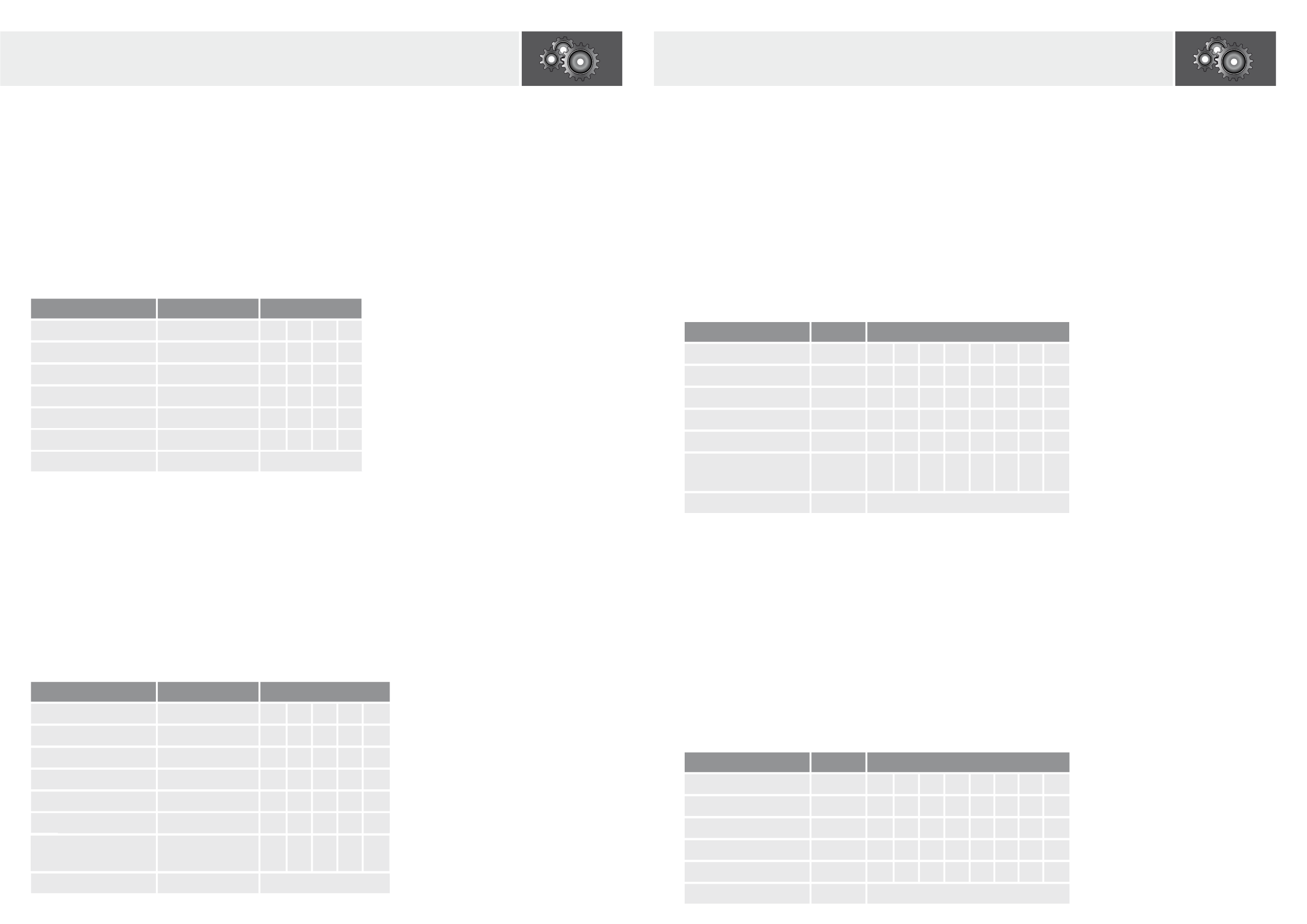

TRANSOL®SP

TRANSOL®CLP

PARAMETERS

PARAMETERS

UNITS

UNITS

TYPICALVALUES

TYPICALVALUES

pourpoint

pourpoint

flashpoint

ability to transfer loads

at theFZG stand

flashpoint

viscosity index

viscosity index

resistance to foaming -

sequence I

sequence II

sequence III

kinematicviscosityat 40°C

kinematicviscosityat 40°C

68

68

66

74

102

102

-28

-28

223

230

100

100

98

103

100

98

-24

-28

230

233

10/0

30/0

10/0

10/0

30/0

10/0

150

150

152

152

99

99

-23

-27

232

236

5/0

5/0

5/0

220

220

223

223

98

98

-23

-27

>12

240

>12

238

0/0

0/0

0/0

320

320

320

299

98

94

-20

-22

240

242

460

460

446

446

95

94

-18

-17

245

246

10/0

10/0

10/0

10/0

10/0

10/0

680

680

1000

1000

650

695

980

990

94

95

94

95

-15

-16

-12

-14

250

250

250

257

10/0

10/0

10/0

0/0

0/0

0/0

mm

2

/s

mm

2

/s

-

-

°C

°C

ml

°C

failure load

stage

°C

ISOVGviscositygrade

ISOVGviscositygrade

PHYSICALANDCHEMICALPROPERTIES:

PHYSICALANDCHEMICALPROPERTIES:

ability to transfer loads

at theFZG stand

of non-destruc-

tive load

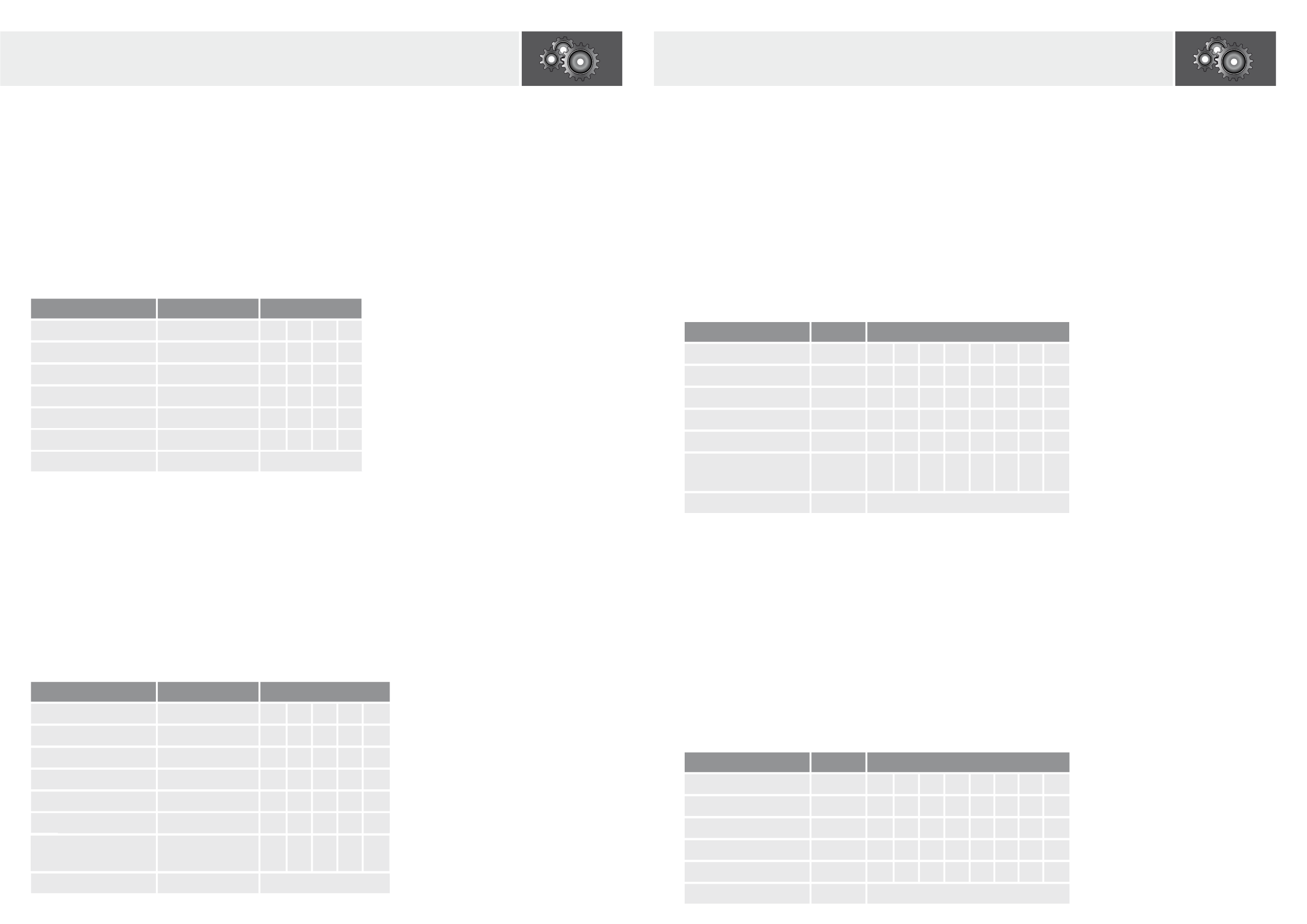

PARAMETERS

UNITS

TYPICALVALUES

pourpoint

flashpoint

viscosity index

copper stripcorrosionplate

100°C/3h

foaming resistance:

sequence I

sequence II

sequence III

50/0

60/0

10/0

-

-

-

30/0

60/0

0/0

30/0

40/0

0/0

0/0

0/0

0/0

kinematicviscosityat 40°C

220

150

220

152

149

147

-38

-38

255

240

1b

1b

320

330

153

-36

270

1b

460

450

150

-33

285

1b

680

690

148

-30

290

1b

mm

2

/s

–

–

°C

rating

ml

FZG test

>12

non-destructive loading

stand

°C

ISOVGviscositygrade

GEAROILS

GENERALDESCRIPTION:

TRANSGEARPAG syntheticoils for industrial gears aremanufacturedbasingonpolyalkyleneglycols. Theyhavebeen

developed for use in extremely high loads andhigh temperatures. Theproduct has the ability to transfer extremely

high loads, it is highly resistant to aging and it provides perfect anti-corrosive protection (withstands ASTMD665 B

procedure). It offers very good demulsifying characteristics, compatibility with commonly used leak stoppers, and

containsnochlorine, sulphur and leadcompounds.

APPLICATIONS:

TRANSGEAR PAG oils are intended to lubricate various devices andmechanisms working at the temperature over

200°C including: heavy-dutymechanical gears of industrial equipment, such as: spur cylindrical gears, helical bevel

gears, spiral bevel gears andwormgears exposed toheavy thermal loads aswell as rollingbearings and slidingbear-

ings and reciprocatingcompressors.

GENERALDESCRIPTION:

TRANSGEARPE industrialgear syntheticoilsareproducedbasingonpoly-alpha-olefins (PAO)andestersaswell asspe-

cially selectedenrichingadditives. Theyhavebeendeveloped foruse inextremelyhigh loadsandhigh temperatures.

Theproduct has the following characteristics: the ability to transfer extremely high loads andperfectly protect gear

elements frommicropitting, high resistance to aging andhigh anti-corrosive protection, perfect filterability, awide

rangeof operating temperatures, extendedchangeperiod.

APPLICATIONS:

TRANSGEARPEoilsare intended to lubricateall kindsof heavy-duty toothedgearsof industrialmachinesanddevices

at risk of micro pitting, operating in temperatures up to 180°C, including: spur cylindrical gears, helical bevel gears,

spiral bevel gears andwormgears calenders exposed toheavy thermal loads aswell as rollingbearings and sliding

bearings. Due to their unique lubricating and anti-oxidation properties they are also recommended for lubricating

wind turbinegearsoperating inharshconditions.

VISCOSITYGRADE:

ISOVG: 150, 220, 320, 460

QUALITYCLASS:

DIN51517part3 -CLP

VISCOSITYGRADE:

ISOVG: 150, 220, 320, 460, 680

QUALITYCLASS:

DIN51517part3–CLP

CincinnatiMachineP-74

APPROVALS:

FLENDERAG–allproducts;

TRANSGEARPE220–GLIMAG,BUMECHSA,

TRANSGEARPE320–GLIMAG,FAMUR,

RYFAMA, BUMECHSA,

MEETSREQUIREMENTS:

USSteel 224;AGMA9005-EO2 (EP)

DavidBrownS1.53.101 typeE

TRANSGEARPAG

TRANSGEARPE

PARAMETERS

UNITS

TYPICALVALUES

pourpoint

flashpoint

viscosity index

copper stripcorrosionplate

100°C/3h

FZG test

kinematicviscosityat 40°C

150

150

195

-30

191

1b

220

237

177

-30

231

1a

320

325

196

-30

225

1b

>12

460

433

220

-28

225

1a

mm

2

/s

–

–

°C

rating

failure load stage

°C

ISOVGviscositygrade

PHYSICALANDCHEMICALPROPERTIES:

PHYSICALANDCHEMICALPROPERTIES: